how hardness test is performed|how to use hardness tester : bespoke Common methods of hardness testing include Rockwell, Brinell, Vickers, Knoop, and Shore hardness testing. Each method uses different techniques to measure the hardness of a . WEB20 de set. de 2022 · A Betmais tem o conhecimento desta informação e preparou uma promoção especial para os apostadores brasileiros. O bônus de boas-vindas da Betmais Brasil é de 100% no primeiro depósito no valor máximo de até R$300. É uma bom valor e uma oportunidade começar bem nas apostas esportivas, colocando R$300 e recebendo .

{plog:ftitle_list}

Resultado da 21 de fev. de 2024 · Keno spielen Erfahrungsberichte: Nur sichere Anbieter sind gute Anbieter. Eines sollte klar sein: Wenn Sie Keno online spielen wollen, sollten Sie dies nur bei einem sicheren und seriösen Anbieter tun. Und genau deshalb setzen wir uns mit den Sicherheitsmaßnahmen der .

In the macro range (conventional hardness range), tests are performed using large test loads ≥ 5 kgf, which also lead to correspondingly large hardness indentations on the test pieces. Hardness test methods in the macro range .

Hardness testing assesses a material’s ability to resist permanent deformation at its surface by applying pressure with a harder material. It finds applications across various industries for .A hardness test is typically performed by pressing a specifically dimensioned and loaded object (indenter) into the surface of the material you are testing. The hardness is determined by .Common methods of hardness testing include Rockwell, Brinell, Vickers, Knoop, and Shore hardness testing. Each method uses different techniques to measure the hardness of a .

Learn about considerations, sample sizes, sample thickness, scales and hardness testing methods in this article about the hardness testing basics.Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Learn more about hardness testing basics here. The Rockwell hardness test method, as . Hardness testing may not be a fundamental physical property, but that does not mean it is not an important property to test and measure. This article discusses methods and the principles behind hardness testing.How to test the hardness of your material, using Brinell, Rockwell, Vickers or Leeb testing methods. The hardness of a material refers to the materials ability to resist deformation, indentation or scratches. It is a measure of the materials .

The typical test uses a 10 mm (0.39 in) diameter steel ball as an indenter with a 3,000 kgf (29.42 kN; 6,614 lbf) force.For softer materials, a smaller force is used; for harder materials, a tungsten carbide ball is substituted for the steel ball. .See also: Hardness. Rockwell Hardness Test. Rockwell hardness test is one of the most common indentation hardness tests, that has been developed for hardness testing. In contrast to Brinell test, the Rockwell tester measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload . Mohs hardness test uses 10 reference materials of varying hardness as the scale for the test. The softest material used is talc (value=1) and the hardest material is diamond (value=10). Given that the references used for .

The Vickers hardness test is ideal for testing of all metals and is therefore the method with the widest range of application. The hardness test method according to Vickers is described in standards ISO 6507 (Metallic materials – Vickers hardness test – Part 1: Test method) and ASTM E384 (Standard Test Method for Microindentation Hardness (1gf - 200 gf) of Materials . The Vickers hardness test can use a test force greater than 980.7N;2. The micro Vickers test force is recommended. Characteristics and Application of Vickers HardnessLeeb Hardness Test. The Leeb hardness test is a non-destructive and portable method used primarily for metals. It involves a spring-loaded end with a spherical or conical indenter. The end that makes contact with the material is released, and the rebound velocity is measured after striking the material's surface.After the test, the preliminary test force is removed and the indenter is removed from the test specimen. Types of Rockwell Scale Table-1 below gives the information on the type of indenter, the magnitude of the major load, and common applications for each of the hardness scales as per ASTM standard E18 (1984).

A standardized test procedure used to determine the hardenability of steel, the Jominy test (End Quench Test) can be performed using either the Vickers or Rockwell hardness test method. When selecting which to use, you should consider relevant standards, as well as the usual criteria when choosing between different types of hardness test.

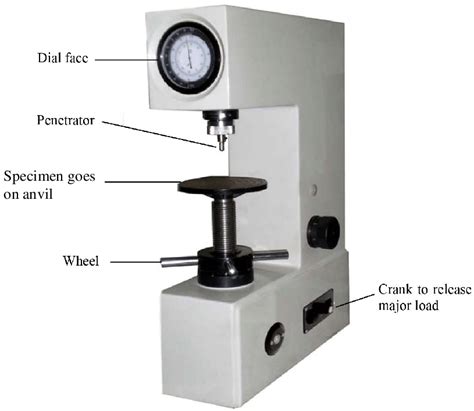

The Knoop hardness test is an alternative to the Vickers hardness test in the micro hardness testing range, and it can be performed on the same universal or micro hardness testing machine. It is mainly used to overcome cracking in brittle materials, as well as to facilitate the hardness testing of thin layers.How is a Rockwell hardness test performed? A hardness number is determined by the difference in depth of penetration after a minor load and then a major load is applied. What is the minor load for a Rockwell hardness test? 10 kg.What is Rockwell hardness testing? The Rockwell Hardness Test is generally a non-destructive test performed on samples when it’s necessary to determine how hard a material is. It’s generally considered easier to perform compared to other methods, like Vickers or Brinell hardness testing. Another advantage is the small area of indentation needed to carry out the .

types of hardness testing methods

The hardness test is a way to assess the quality of a material, determine its properties, and evaluate its suitability for a specific application. What is Hardness Testing? Hardness testing is a mechanical test that measures a material’s resistance to indentation, scratching, or abrasion. The test is performed by applying a specific force on . This article provides an overview of common hardness testing methods for metals, comparing their applications, benefits, and drawbacks. en – EU . Knowledge & Community . Knowledge & Community You are . Knoop Hardness Number (HK) tests can be performed with loads ranging from 10 gf to 1,000 gf, allowing for detailed hardness analysis of .

Instead, the value of a material’s hardness is the result of a specific measurement procedure. For most materials of the modern age, a hardness test has usually been performed through a device that measures depth of an indentation left by a point of a specific shape, with a specific force, and for a specific amount of time.

A mould hardness test is performed in the foundry to determine the hardness of the mould after the ramming of sand is done. The mould hardness test is important for the good hardness property of moulding sand. The sand .Angles of a Knoop hardness test indenter. The Knoop hardness test / k ə ˈ n uː p / is a microhardness test – a test for mechanical hardness used particularly for very brittle materials or thin sheets, where only a small indentation may be made for testing purposes. A pyramidal diamond point is pressed into the polished surface of the test material with a known (often 100 .This eLearning course focuses on Rockwell and Brinell hardness testing and Vickers and Knoop microhardness testing. Participants will learn about how the tests are performed, test sample requirements, test parameter selection, and testing requirements. The course can .

Indentation hardness value is obtained by measuring the depth or the area of the indentation using one of over 12 different test methods. Hardness testing is used for two general characterizations 1.Material CharacteristicsHigh Rockwell hardness numbers represent hard materials and low numbers soft materials. d 2 www.wilsoninstruments.com Fundamentals of Rockwell Hardness Testing Like the Brinell, Vickers, Knoop, Scleroscope and Leeb tests - all of which fall in the general category of indentation hardness tests - the Rockwell test is a measure of the A portable hardness tester (Brinell hardness) can be performed on the actual job with minimal surface preparation can be considered as a Non-Destructive Testing type of hardness. Hardness testing is a quantitative test method.

Hardness generally refers to the resistance of a material to scratching or indentation, and a qualitative measure of the strength of the material. The most commonly used hardness tests are the Rockwell test, Brinell test and the Vickers hardness test. This article will provide an introduction into durometer hardness and the gauge used to . The 50 kN capacity and the fully variable test speed of 0.2 to 51 mm/min make it possible to perform not only the CBR and Marshall tests, but many other applications as for instance Indirect Tensile test, Quick Triaxial tests, Unconfined and Uniaxial soil testing and, in general, all test to be performed under displacement control.Questions Q1- Why hardness test are performed more often than any other mechanical tests? Q2- Why the hardness testing machine is called 'Universal Hardness Testing Machine"? Q3-Should brittle materials possesses larger hardness number? Give reasons to your answer? Q4- If the specimen material is softer, what will be the effect of its hardness?A Knoop hardness (HK) test is performed on a nickel plate. A load of 2500 kg produces a pyramidal indentation whose outer legs measure 7.7 mm. Calculate the HK of this alloy.

Vickers hardness test is a standard method for measuring materials' hardness, which is commonly used to measure the hardness or softness of substances like metals, minerals, and plastics. . The test method is usually performed with a hardened steel ball pressed into a flat surface of the material being tested. The Vickers hardness can be .

list of hardness tester

residual gas analyzer price

The Brinell hardness test method as used to determine Brinell hardness, is defined in ASTM E10. Most commonly it is used to test materials that have a structure that is too coarse or that have a surface that is too rough to be tested using another test method, e.g., castings and forgings. Brinell testing often use a very high test load (3000 .

Over the years, several hardness-testing techniques (like Brinell, Vickers, Knoop and Rockwell) have been developed, and each one has its own scale. . Data analysis was performed by V.D.F. A.B.H .

emerson process gas analyzers

how to use hardness tester

Resultado da Roblox

how hardness test is performed|how to use hardness tester